Spring cleaning isn’t just for your home! As the weather warms up and the sun comes out, it can shed a light on areas of your property that may need some attention. While these tasks can be time intensive and not always fun, they’re crucial tasks to perform. When tasks such as these are ignored, it can pose safety issues, and even compliance issues. We worked with our VP of Safety & Risk Management, Steve Pomponi, to identify 9 key tasks and best practices to help keep risk in check.

9 Commonly Overlooked Practices That Definitely Count as Spring Cleaning:

- Perform a formal PPE Hazard Assessment.

Many companies might not realize that even though they issue PPE, provide training, and enforce regulations, they could still be cited by OSHA. A little-known section of the Standard requires companies to perform a formal PPE Hazard Assessment in their workplace. This requires you to survey each position to determine exactly what PPE is required. You must evaluate the hazards for each body part and then determine if it can be engineered out first, and if not, what PPE is required to protect the employee. This information should then be certified by a workplace safety professional.

Note: PSA has forms and checklists to help you avoid missing exposures, upon request. - Organize chemical safety data sheets and label secondary containers.

Many companies who have chemical materials are still not compliant with the Globally Harmonized Standard (formerly known as Hazard Communication). If you haven’t already, any old Material Safety Data Sheets (MSDS) should be replaced with the new standardized Safety Data Sheet (SDS).Review your chemical information list (or build one as required by the standard) and use it to make sure you have updated your SDS library. Simply go to each manufacturer’s website to download the new SDS. Along with the requirement for updated SDSs, updated labeling is required. Now is the time to update all primary and secondary containers with the new labels. Check out an example of what the updated chemical container label looks like.

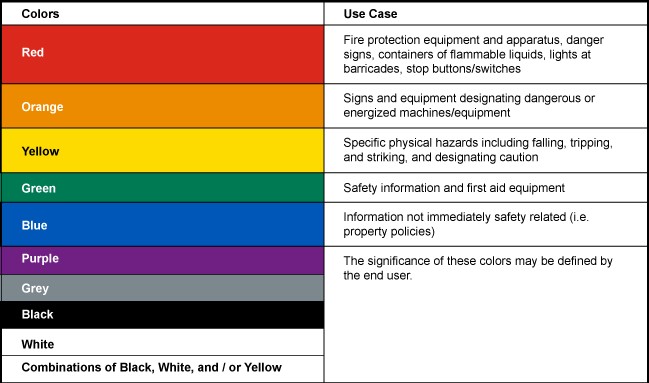

Note: PSA has a handful of vendors who can take care of this process for you. - Touch up safety color-coding and equipment labels.

This is a fun one! Repaint those worn out, barely still yellow guardrails, walkway lines on the floors, changes in elevation markings, etc. Here is a summary of color codes: - Organize and update workplace safety files and programs, paperwork, and documentation.

Check your written safety programs and revise them if necessary. If your current program hasn’t been revised since 2014, it’s time to review and revise. Take the time to make your safety program industry specific and relevant to your company.

Note: Now is also the time to develop forms to document your efforts like self-inspections, vehicle inspections, and safety training attendance. Remember, in both OSHA’s and an attorney’s eyes, if it isn’t in writing, it never happened. - Prepare a safety training matrix.

A safety training matrix is simply an electronic document that captures the following:

– employee’s name

– the safety training and/or certification they are required to have by position

– completion date

– expiration date

Staying organized with a matrix saves you time and helps you stay compliant and up to date on required trainings.

NOTE: PSA Clients are provided a listing of all OSHA standards that can be used as a foundation to build your safety matrix. Now is also a great time to deploy online safety training services for employees that may be idle. Contact us for a list of reputable on-line training vendors. - Update your workplace safety inspections and forms for ladders and guarding.

Take the time to inspect ladders, especially the ones that might not be used regularly. Look for damage such as cracks, bends, sharp edges, dirt, grease, and missing warning labels. You might find this sample ladder inspection checklist helpful. Survey your machinery for adequate guarding and make the appropriate repairs and changes. Is it loose, or has an employee removed guarding, tampered with it, or bypassed it? Field services employees are notorious for removing the guards on angle grinders; check your gang box and see what you find.

[psa_cta id=”14000″]

- Write JSAs for your core tasks.

JSA, or a job safety analysis, is a technique that focuses on identifying hazards in a specific job or task before they occur. After identifying jobs that have caused historical losses, or jobs that have the most potential for a serious or fatal injury, you simply list out the steps to eliminate or reduce the uncontrolled risks. - Review and update machine-specific energy control procedure.

Many clients have a written program for the Control of Hazardous Energy or Lockout/Tagout (LO/TO). But just like the PPE Standard discussed above, there is a section with which many companies are not in compliance. Employers must develop, document, and use procedures to control potentially hazardous energy. The procedures explain what employees must know and do to control hazardous energy effectively when they service or maintain machinery. If your business only uses similar machines (those using the same type and magnitude of energy) that have the same or similar types of control measures, then they can be covered by a single procedure. Otherwise, you must develop separate energy-control procedures if you have more variable conditions – such as multiple energy sources, different power connections, or different control sequences that workers must follow to shut down various pieces of machinery. The energy-control procedures must outline the scope, purpose, authorization, rules, and techniques that employees will use to control hazardous energy sources, as well as the means to enforce compliance. Learn more about LO/TO program on OSHA’s resource page. - Conduct a wall-to-wall workplace safety inspection.

When was the last time you went over your facility with a fine-tooth comb? I’m not talking about your one-hour, quick survey. I mean checking every electrical cord for damage, every breaker box for required labels and identification marking, every disconnect switch for identification markings, every electrical outlet to make sure it’s safe, and all chemical container labeling checks. OSHA may do it, so beat them to it.

Contact PSA, a Hilb Group Company

PSA Insurance & Financial Services has a wealth of knowledge and experience when it comes to commercial insurance and safety practices. Our team can provide you templates to follow to perform comprehensive wall-to-wall mock OSHA inspections of your workplace. We can also provide you a guide to prepare for a carrier loss control. Connect with a member of our Commercial Risk team or with Steve Pomponi to learn more about risk mitigation in your workplace.

Also, don’t forget to check out our last post on ways to protect your unoccupied buildings and storage yards from theft to improve safety during the pandemic. For further risk and safety management services and other resources visit our commercial risk page.